Quality Plates for the Flat Lapping Process

At H.K Founders Ltd, we supply premium cast-iron lapping plates for all types of industrial applications, especially for the silicon and quartz wafer industries. Call us for more details

Plates for Flat Lapping Processing

Our high quality lapping plates are available in different specifications, (from 500mm to 2100mm diameter) for Peter Wolters’ AL2F and AC range, Fujikoshi and Speedfam, and Mitsunaga double-sided lapping machines.

Single-sided lapping plates are available for Peter Wolters and Hoffman machines.

Our plates are custom-made in ISO 9001 registered facilities, and are supplied in a grooved style or machined flat.

Send us your drawing for a quotation.

We also provide plates for ball manufacturing Worldwide.

Types of Lapping Plates

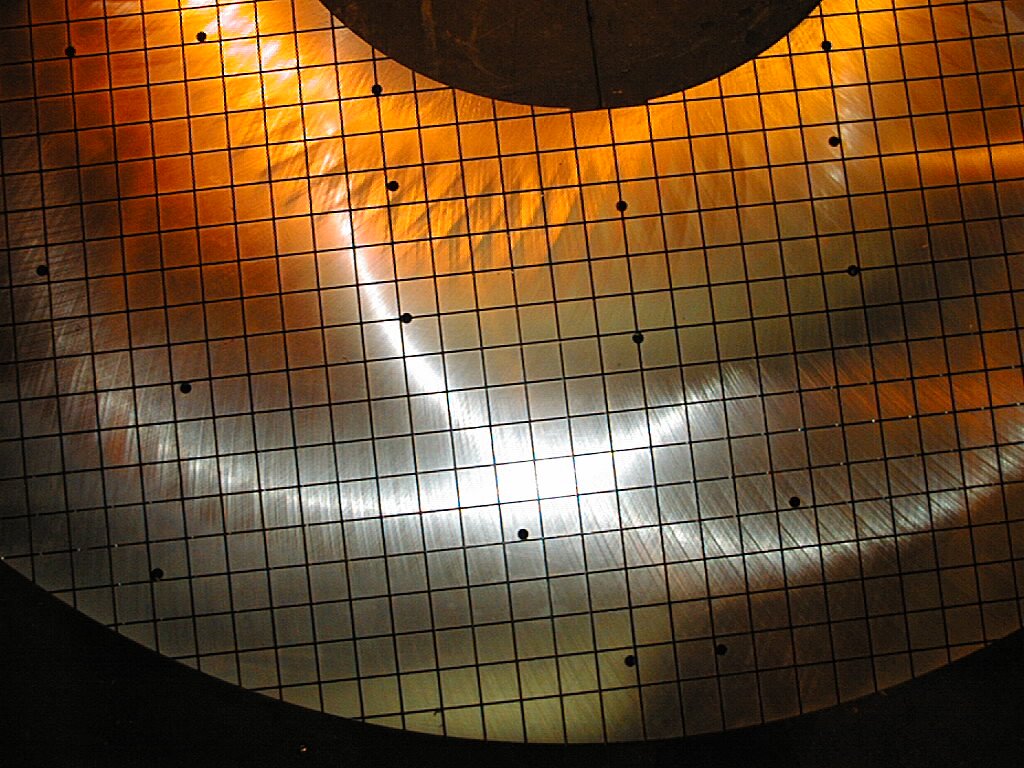

Cross-hatch

Our cross-hatch grooved plates are fully machined to suit individual machines, and are available in sets of upper and lower plates.

The sizes available are 800mm to 2200mm in diameter, at a thickness to meet the machine’s requirements.

silicon wafer, quartz wafer, mechanical parts, optical and ceramic components production.

In order to provide a thorough hardness, to enhance longevity, to improve wafer TTV and to minimise scratch rates, all plates are cast and heat treated.

Grooves are machined at pitches to our specifications or as per our customer’s requirements. All plates have an individual number. This is to provide product traceability and the continuous monitoring of performance.

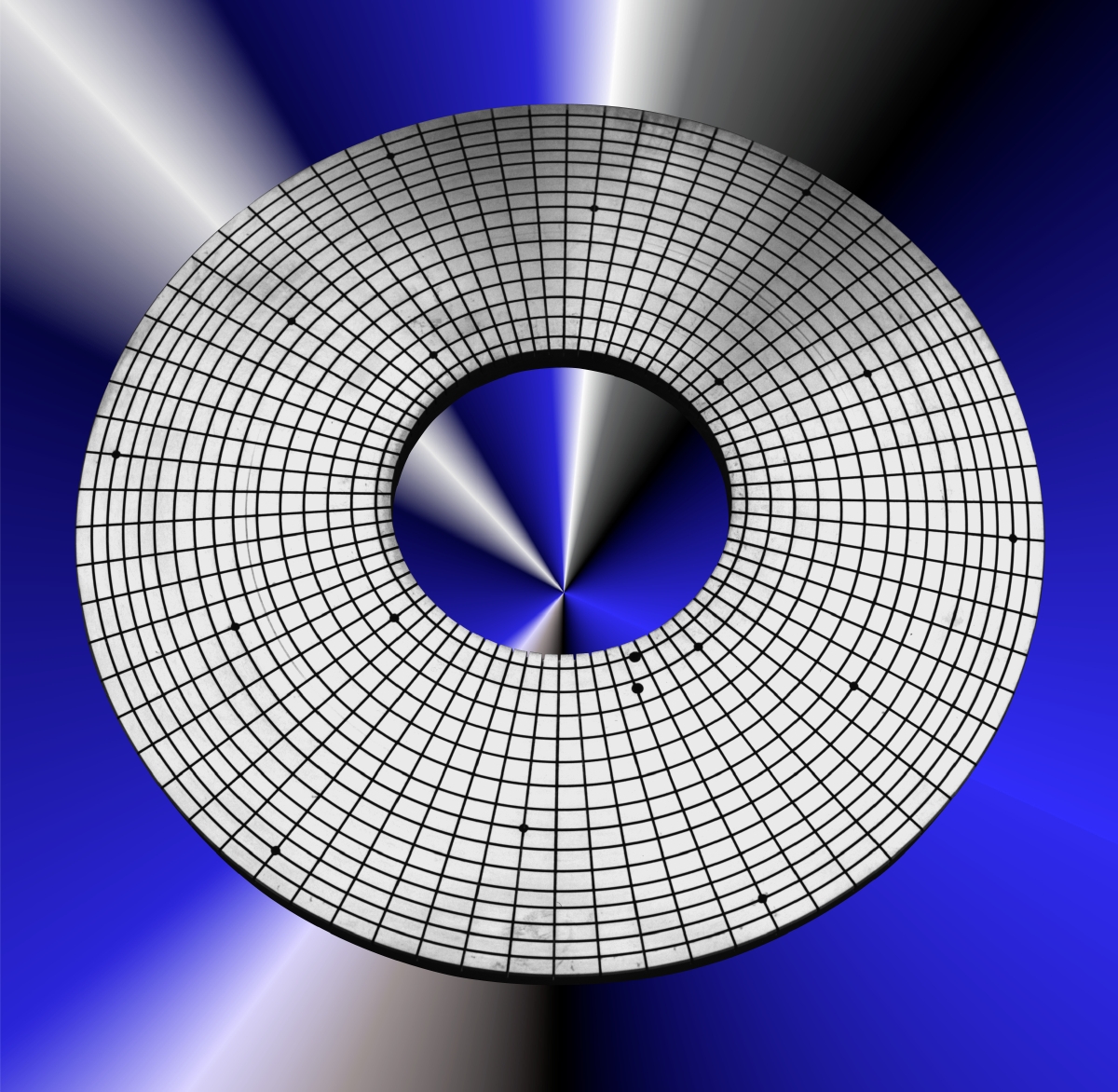

Radial

Radial grooved plates are made from our martensite material in order to improve life expectancy.

They’re available in plates up to 1000 mm diameter and are supplied for silicon wafer, quartz wafer, mechanical parts, optical and ceramic components production.

Groove pitch is machined on a 4-axis computer controlled machining centre in a controlled environment, as per customer’s requirements.